Beyond Stick Built: A Log Cabin Rebuild

This article is reprinted with permission from McKenzie Magazine, McKenzie Bridge, OR.

Frank and Betsy Pitcher thought they would continue to enjoy their log house just east of Blue River, Oregon. Like many others, though, fire took not only their vacation getaway but all the trees on their heavily wooded riverfront lot.

The Pitcher’s fire aftermath, though, had some good news. “We had terrific insurance,” Betsy is happy to report. Unlike so many of the horror stories she’s heard from others, Country Financial acted quickly, sending a check that fully covered their losses and in just 2 weeks.

“There were no lists, no nothing,” she says. During a phone call to an agent in Illinois, he simply told her, “Your house burnt down, you have insurance.”

With that go-ahead the couple decided to replace their log home in the same manner they used when they first built it in 2003 – ordering a replacement from Timberhaven Log & Timber Homes.

The Middleburg, Pennsylvania-based company sells complete homes that are delivered to the homesite ready to be assembled. Timberhaven advertises their offerings as, “a one-stop service” available at a surprisingly affordable price.”

Frank says Betsy wasn’t sure about the price part, but he reminded her there were plenty of savings if, “You don’t have to keep going back to Jerry’s to get much when the kit includes more.”

That’s proven to be true because Timberhaven’s kits are shipped with more of almost all the individual items needed to build a home. The only things not included are the flooring, plumbing, electrical fixtures, etc.

All the components needed to construct a log cabin are packaged and shipped from the factory. The Pitcher’s home arrived on 3 semi-truck loads. Before leaving the Timberhaven factory a photo was taken of each load so the purchaser can compare it to what arrives on their land. Betsy approves the process, saying it was much simpler than trying to match everything to a printout list-like they did with their first cabin kit.

Beyond Stick Built: Log Cabin Construction

Helping out with the construction process was a father-son team of Todd and Brandon Mitchell. Traveling the US, the Mitchells are part of a construction support services Timberhaven offers – in addition to custom designs, engineering and complete packages.

Beyond knowing what was delivered, the Mitchells also had arrived to go to work. Over the next 6-7 weeks, they assembled the home’s walls, rafters and roofing. This time around, rather than natural logs, the new cabin was built using “engineered logs.” For that process, raw materials go to the sawmill like a regular log, where they are cut and kiln dried. Sections are then glue-laminated, followed by rounding of the edges to reassemble traditional logs. Manufacturers say engineered pieces are not only resistant to warping, shrinkage and settling, they’re also stronger than a single piece traditional log.

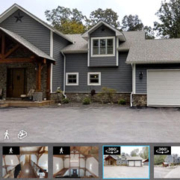

Now that the cabin has been completed, a number of passersby have been commenting at how attractive it looks. One, though, was a long haul trucker who’d delivered a load of materials. After stopping on his way heading east, the smiling man walked up their driveway admitting he’d always been curious about the big packages on his truck because, “I never knew what you bought.”

Thank you for choosing Timberhaven Log & Timber Homes to help rebuild your beautiful log home, Frank and Betsy. Thank you, McKenzie Magazine for allowing us to re-share your story.