International Log Home: Bound for the Netherlands

Timberhaven’s team of experts has vast international log home experience having shipped log homes internationally to over 20 foreign countries to date. So when we received a request from a prospect to ship a log home to the Netherlands, we embraced this opportunity with open arms! Although there are some additional requirements associated with shipping internationally, we knew our knowledge and experience from past projects would help us in satisfying another log home dream.

Click to watch:

Each project can present its own set of unique obstacles, but no challenge is too big for the Timberhaven Team.

The first hurdle we encountered for this Netherlands project? The lack of a loading dock at our new facility. So the first step was to build one! This enabled us the opportunity to load the sea containers at our manufacturing facility thus streamlining some of the logistical complications that would otherwise be involved.

Manufacturing an International Log Home

Our manufacturing process began with the planing and profiling of the logs and timbers. Over 2,800 lineal feet of logs were required for this project, and our 6×8 D shaped traditional solid logs were utilized. Our trained experts inspected and graded these materials complying with the stringent guidelines set forth by the Log & Timber Home Council. Upon completion, the logs were transferred to the next phase of the manufacturing process, the pre-cutting of a heavy timbered roof system.

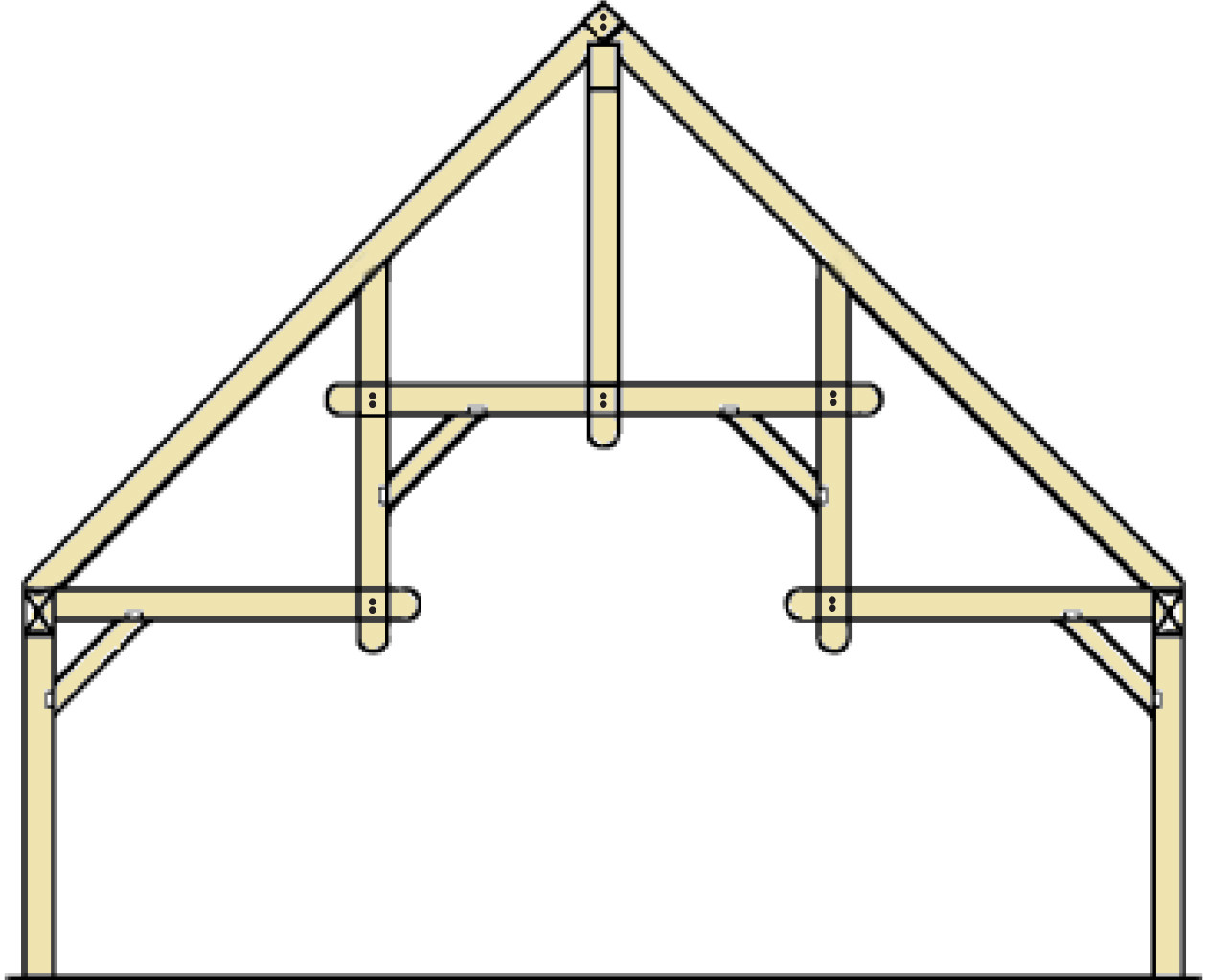

This client selected our Beam & Purlin A-style roof system. The heavy timber option is both exposed and structural and is comprised of 6×8 beams, purlins and collar ties. During the manufacturing process, the beams were sanded, pre-cut, and notched for ease of assembly at the job site. Once delivered, they will be installed and fastened with gusset plates and hardware. The completed roof system looks like this. It’s stunning. Wouldn’t you agree?

Now… the logs are transferred to the cutline where they will be precision crafted to ensure each member fits together perfectly as part of an ornate puzzle. This includes the following builder friendly pre-cutting processes:

- All logs to exact lengths and tolerances

- Window and door openings

- Mortise & Tenon corner assemblies

- Spline joints and

- Roof pitch angles on solid gable logs

Logs are also pre-drilled and counter sunk for lag bolt placement, and an additional quality control inspection verifies these processes have been completed to our exacting tolerances.

Shipping an International Log Home

After the logs are inverse stacked on custom pallets, they are wrapped, banded and labeled to identify log rows contained within. We construct these custom pallets for all international projects due to the fact that sea containers can only be loaded from the rear as opposed to the typical methods utilized for a flat bed trailer.

Other requirements for all international log home shipments include a sanitizing heat treatment — inspected, verified and documented by an FDA official.

Timberhaven’s final phase of this international log home project involves the loading of sea containers. Our manufactured materials are staged, bundled, wrapped and readied for loading. Additional package materials such as windows, doors, shingles and insulation are also gathered and prepared for shipping.

As you see here, the Timberhaven Team utilizes extreme care to ensure the materials are kept in excellent condition for their entire journey.

Once the loading process has been completed and the materials have been secured in their temporary home, the sea containers are sealed and transported to the nearest port of call. From there, they are loaded onto a cargo ship for the remaining voyage to the Netherlands.

Thank you for choosing Timberhaven Log & Timber Homes for your international log home project – we were honored to be part of it.