Manufacturing Process: Planing, Profiling & Inspection

Hello! Welcome to Timberhaven Log & Timber Homes. Today we are going to focus on our manufacturing processes, specifically we will be looking at planing, profiling, and the inspection of our log and timbers. For complete details, keep reading — or simply click to watch the video below.

Manufacturing Process: Planing and Profiling

Whether we’re talking about solid logs or our premium engineered logs, both are kiln-dried products and start in the form of a cant. What is a cant you may ask? Simply put, a cant is a large, over-sized unfinished log or timber, typically slabbed on one or more sides.

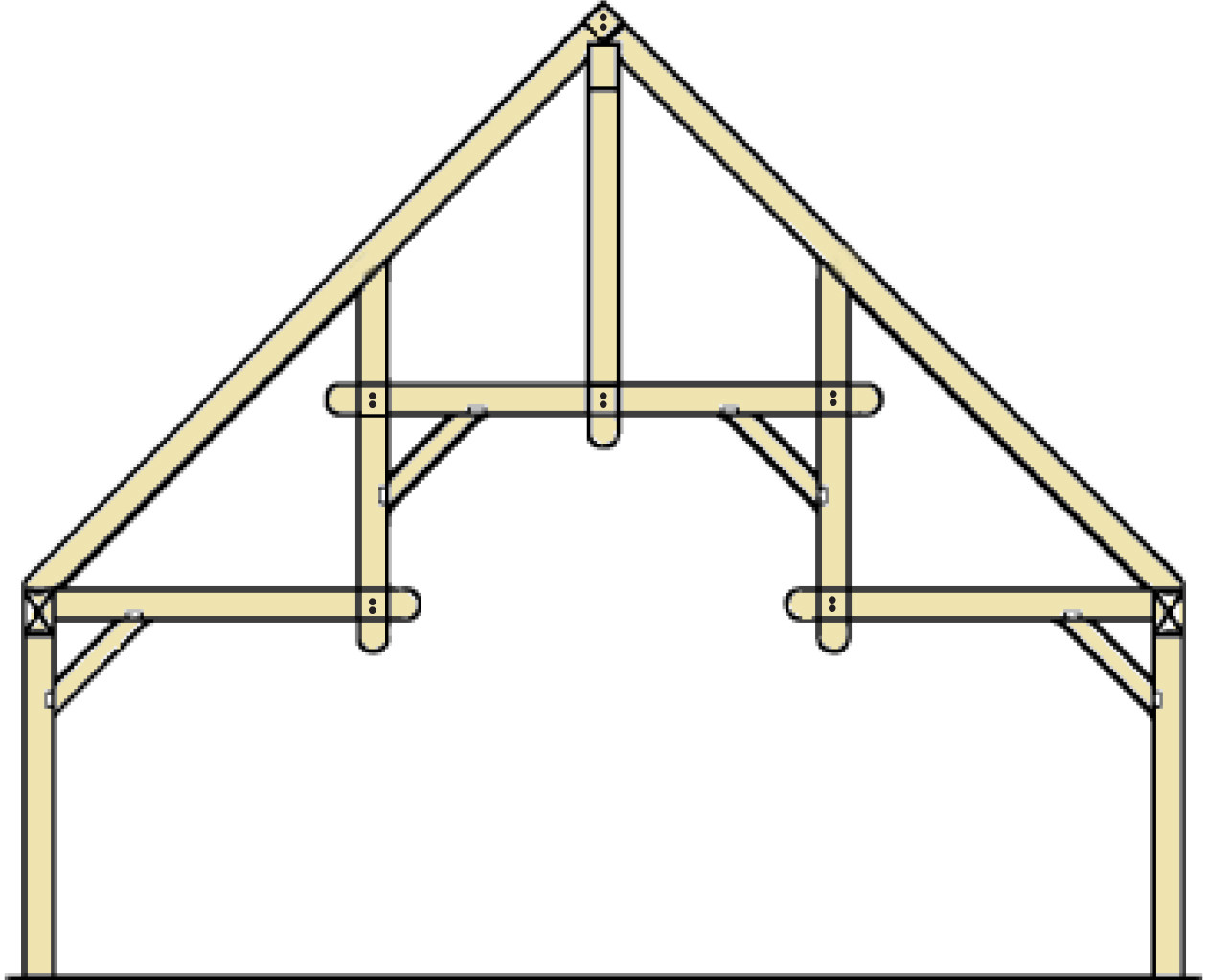

In this case, solid cants are loaded onto the conveyor system which will ultimately be directed into the planer mill. The cants are visually inspected and positioned in such a fashion to ensure maximum aesthetics are achieved. The cants are then fed into the machinery for the next step of the process. As the cants pass through the 8-ton planer mill, a series of cutting heads will transform them into their finished size and shape.

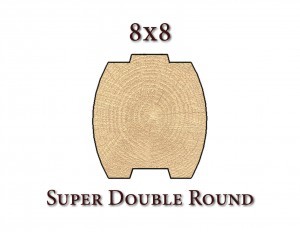

Here is an example of one of the cutting heads used for this particular project. In this case, our clients selected the 8×8 super double round with single tongue and groove as their log profile utilizing Eastern White Pine material.

After the log profiling process has been completed, the newly milled 8×8 super double round solid logs continue down the conveyer system until they are redirected to the next step which is the inspection process.

Manufacturing Process: Inspection

Once the logs reach the quality control line, we utilize the stringent grading standards set forth by the Log and Timber Homes Council to visually inspect and grade out any naturally occurring or manufacturing defects. Some example defects include loose or oversized knots and checking (also known as cracking) that exceeds the allowable grading tolerances. Our certified grading experts mark out or red-line these defects to indicate these materials are not to be utilized in any of our home packages. The graded and marked logs are carefully stacked onto a rolling cart. They are then moved to the pre-marking area for the next step in the manufacturing process.

Manufacturing Process: What’s next?

In our next video, we will highlight the premarking, precutting and inverse stacking processes, and we will share with you the meticulous steps we take for each and every one of our Timberhaven homes.

Until then, be sure to check out our website at www.TimberhavenLogHomes.com or give us a call at

855-306-5678.